Conventional SCR controllers typically use simple analog and discrete digital signals to control and supervise operation of the product, whether it be an SCR controller for heaters, an SCR controlled rectifier, or an SCR motor control. However, as customers expect more and more out of our products, this simple user interface limits our ability to provide value add in the products we design.

The OZSCR-1000 SCR Controller overcomes this limitation by providing a MODBUS serial interface in addition to the conventional control interfaces. While the MODBUS interface provides a simple means to configure the product, it also opens the door to advanced features. Using MODBUS, the user can:

• Implement sophisticated architectures employing multiple control boards

• Monitor system performance using fault and instrumentation data

• Provide improved maintenance & trouble shooting using detailed fault and performance data

MODBUS is one of the most popular industrial communication protocols in use today. It’s simple, inexpensive, and easy to use. MODBUS was developed in 1979 by Modicon (now Schneider Electric) for use in communicating with multiple devices over a single pair of twisted wires. While the original implementation operated over an RS-232 hardware layer, today’s MODBUS devices run over virtually all communications media, including wireless, fiber, ethernet, etc. Today, MODBUS-IDA (www.MODBUS.org), the largest organized group of MODBUS users and vendors, continues to support the MODBUS protocol worldwide.

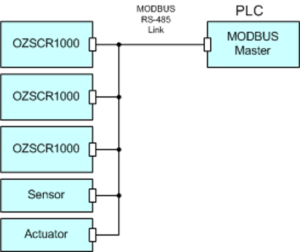

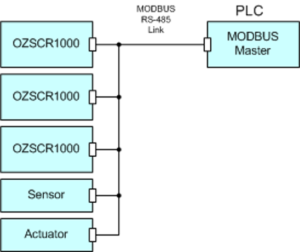

The OZSCR1000 implements the MODBUS RTU protocol over an RS-485, multi-drop, serial interface, allowing many devices to operate on a single pair of twisted wire. The following figure illustrates a typical system with a PLC serving as the MODBUS master controlling several slave devices: