Does developing and manufacturing your own custom power conversion system seem like a good idea that can save your company time and money while helping you retain more control over your end product?

Before you leap headfirst into designing and building your power conversion system in-house, you need to weigh the pros and cons, make sure you have the right resources, and consider the strain it might put on your workforce.

Factors affecting power electronics manufacturing can be divided into two basic categories: external and internal. Before you consider your company’s abilities to design, build, and support power conversion systems in-house it’s important to first look closely at factors outside your organization that can have a positive or negative impact on in-house power electronics manufacturing.

External factors can include:

Market demand Are the economic and political environments of your market and demand for your end product stable enough to warrant the added investment of time, money, and additional equipment purchases that may be necessary to begin developing and manufacturing your own custom power conversion systems?

Supply chain dynamics If you need to buy power conversion system subcomponents internationally, how easy is it for you to purchase and receive those subcomponents to be able to reliably and economically manufacture your custom power conversion system? Can you ensure their delivery, compliance, and traceability?

Service and warranty management Likewise, if you sell your end product worldwide, can you safely, efficiently, and economically support your custom power conversion system in the field?

If external factors look favorable, it’s time to look closely at the internal ones, including:

Core competencies What do you consider to be your company’s core technical competencies? Power electronics hardware design and their control are specialized engineering competencies. If your engineering department’s responsibilities largely consist of integrating vendor components, is it realistic to expect them to be able to design, debug, and qualify a state of the art power switching converter? Can you afford the added cost in time, money, resources and risk that come with learning on the job?

Hiring Engineering Talent Human resources are one of the most time consuming and riskiest elements of running a successful business. If you’ve recognized the need to add engineering skills to your group, you must also consider the associated risks; will the engineers I hire ultimately have the proper skill set, will they be able to bring a design to market within the required time frame, can they support the product in the field. An often over looked risk is whether or not there will be sufficient long term work to retain your talent. Too often companies are lucky enough to find talented designers only to lose them for lack of interesting work. This is the worst possible scenario, as not only has your business lost its technical investment, but now you have a product with no resources to support it.

Engineering bandwidth Is your new power conversion project one plate too many for your engineering group to be spinning, especially if it’s not within their daily scope of work or if it takes away from other critical tasks or projects?

Time to Market Getting your product to market within a required timeframe is often one of the most critical factors in a products ultimate success. Is the decision to go in-house going to take more time and pose more risk than if you were to use a vendor’s custom or semi-custom solution?, If so, will that adversely affect your competitive position and product time-to-market?

Ability to qualify a power electronics product Does your engineering group have the experience and expertise to confidently qualify a critical component such as a power conversion system? Quite often qualification testing of power electronics can take as long and cost as much or more than the design phase. Proper attention to product qualification ultimately helps ensure product reliability, quality, and success.

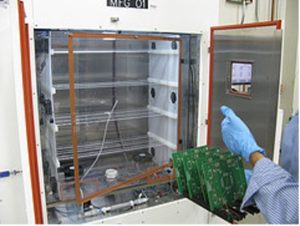

Manufacturing capabilities It’s one thing to design and build a prototype or a one-off device, it’s quite another to consistently and reliably build and support the number of power management components that may be involved in a sizable project or an ongoing new product line. Do you have the infrastructure and resources to maintain and support production-level manufacturing?

Quality assurance and testing Does your team have the expertise, experience, and resources to adequately provide manufacturing test solutions to test and validate your custom in-house power conversion system?

Product/component cost is usually the major consideration for deciding to go in-house with a custom-built, application-specific power conversion system. However if soft costs, such as salaries, space, manufacturing equipment, test equipment, and other related expenses — are included, the actual system cost can be as much as twice that of outside vendors. This is escpecially true if these internal costs are not shared with other products or product lines.

It’s important to realize that the decision to manufacture power electronics in-house requires a commitment to making it a company core competency, and that requires investment that will only make sense if spread out over a number of ongoing programs.